Focusing on creating the cutting edge thermal imaging technology, the R&D team of Senopex continues to innovate and push the boundaries of the industry.

Our highly-qualified scientists come from the most prestigious universities including MIT, Oxford, and the Chinese Academy of Sciences, working together to set new standards in the thermal world.

The team also receives support from the National Institute of Optics in the development of our thermal imaging products.

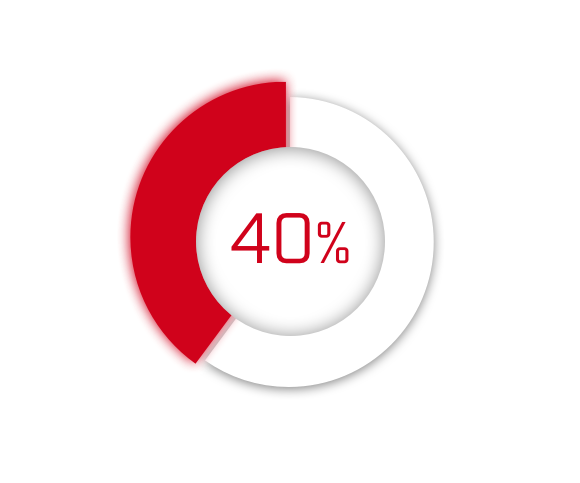

Senopex invests heavily in R&D and quality control, allotting around 40% of our annual profit to those departments that allow our teams to create, innovate, and fast-reacting to the feedback of our clients. Our commitment to providing transformational change ensures our clients could get premium thermal imaging products in the market.

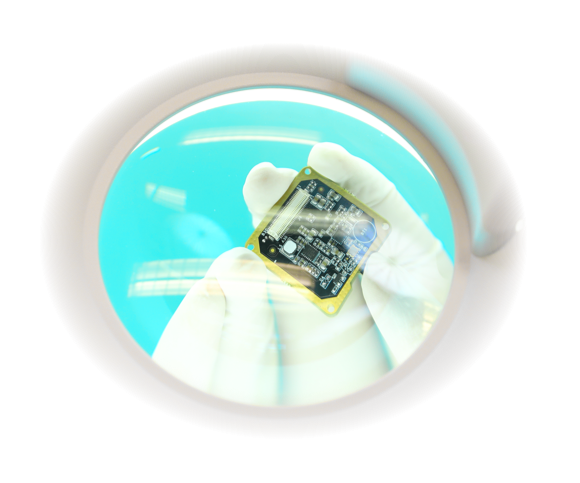

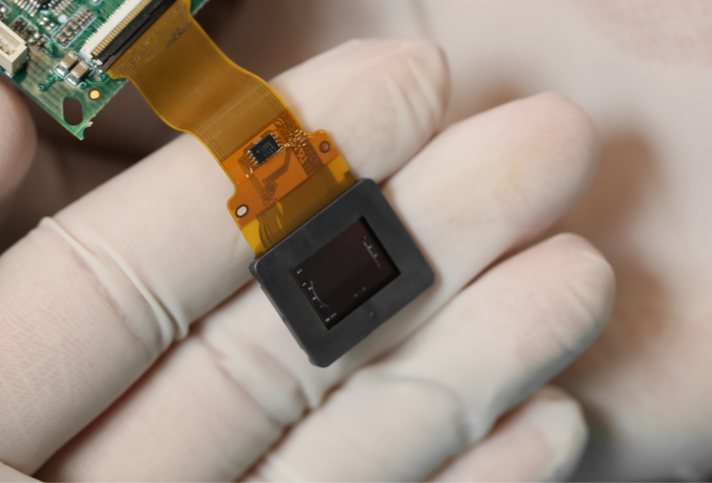

We are proud to design and manufacture thermal core ourselves.The thermal detectors of Senopex are designed and manufactured based on wafer materials from trustworthy suppliers like Lynred. In order to achieve even better performance such as high sensitivity, low power consumption and overall reliability, Senopex conduct wafer-level packaging by ourselves thank to the powerful and strong R&D team.

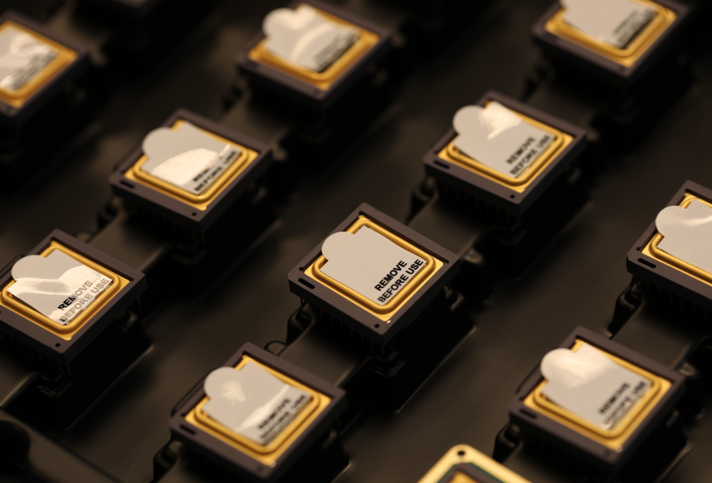

OLED screens installed on each thermal imaging product go through several quality checks, ensuring they offer a pixel-to-pixel match with the sensor for the clearest possible image. All devices of Senopex utilize military-grade OLED screens that can be used in extreme weather conditions while presenting the best level of image quality.

The objective lens is the core component of a thermal imager. In order to achieve the perfect image quality, Senopex offers a large aperture F1.0 germanium lens for every device in the product portfolio. Expertly crafted lenses are carefully calibrated before installation to ensure uniformity of the images, incredible image quality, and an accurate response rate.

Device housing decides the general lifespan of a military standard equipment. Our devices utilize hard-anodized aluminum alloy housing without any plastic parts to ensure the best endurability.

To facilitate the efficient manufacturing of thermal imaging products, our 2000-square meter factory houses a state-of-the-art production line and optical laboratories that handle various testings.